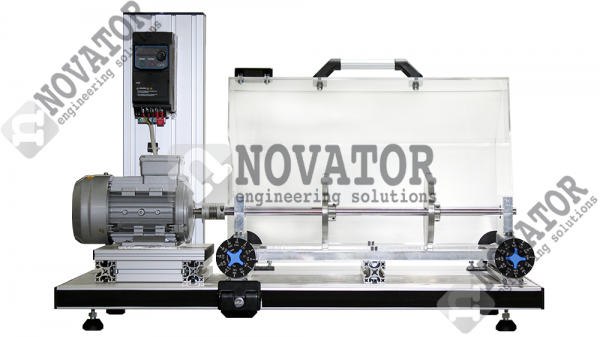

Machinery Fault Simulator Lite (MFS-LT)

|

|

|

PLANB_FULLICONS-ONE

PLANB_FULLICONS-TWO

PLANB_FULLICONS-THREE

PLANB_FULLICONS-FOUR

PLANB_FULLICONS-FIVE

? Ask a question

Description

A Valuable Tool for Learning Machinery Diagnosis

To gain an in-depth understanding of different vibration signatures, controlled experiments on a device that emulates real world machinery are needed. While analysis of a single machinery fault may be beneficial, there are many occasions when the analysis of the interaction between dynamic stiffness, resonance, and speed is essential in order to gain an understanding of real world vibration spectra. With the MFS, the expertise required to diagnose industrial machinery problems in well controlled experiments can be developed and enhanced. With a plant running at full production, it is virtually impractical to gain an understanding of the kinetics and dynamics of machinery without adversely affecting production and profits: The MFS-LT enables offline training and experimentation which in turn will minimize production downtime.

Features

- Simple methods for introducing controlled and calibrated faults.

- Study the vibration spectra of common faults, learn fault signatures and validate rules provided in training courses.

- Bench top machine for hands-on training and skill sharpening.

- Learn machine condition monitoring and predictive maintenance.

- Manual with exercises for individually paced study.

- Learn resonance and variable speed diagnostics.

- Learn to determine vibration transmission path and perform root-cause analysis.

- Validate balancing procedures above and below the first critical resonance.

Basic Machinery Fault Simulator – Lite System includes:

- 1/2 HP variable frequency AC drive with multi-featured front panel programmable controller

- 3 Phase, 1/2 HP motor, pre-wired self-aligning mounting system for easy installation/removal

- Built-in tachometer with LCD display and one pulse per revolution analog TTL output for DAQ purposes

- Split bracket bearing housings with features for span reconfiguration

- Two rolling element ball bearings with squeeze lock type

- Vibration isolators mounts and base stiffener

- Two balance rotors with two rows of holes

- Alignment system with calibrated reference dials and jack bolts

- One 5/8″ TGP straight steel shaft

- Impact resistant clear safety cover with safety interlock

- Balance weight kit

- Allen wrench set

- 24V Power supply

- Cover support

- Comprehensive operations manual

High Value Combination Packages

The MFS-Lite provides a basic setup for performing experiments and learning vibration signatures of different machine malfunctions. However, a detailed investigation of particular and more advance vibration phenomena or machinery fault will require additional attachments and fixtures which are available through optional kits. Depending on the package selected, you get a 6% to 8% discount over separately purchased items.

| Package # 1 : | Basic MFS-LT+ Kits for in-depth studies of alignment, balancing and resonance issues |

| Package # 2 : | Basic MFS-LT+ Kits for in-depth studies of alignment, balancing, resonance, and bearing defects issues |

| Package # 3 : | Basic MFS-LT+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, crack shaft, fan vibrations, mechanical rub & damping issues |

| Package # 4 : | Basic MFS-LT+ Kits for in-depth studies of alignment, balancing, resonance, bearing defect, crack shaft, fan vibrations, mechanical rub, damping issues; plus PC Operation, shaft alignment, and both bearing horizontal and vertical forced measurements |