Training kit Flexible manufacturing systems

|

|

|

PLANB_FULLICONS-ONE

PLANB_FULLICONS-TWO

PLANB_FULLICONS-THREE

PLANB_FULLICONS-FOUR

PLANB_FULLICONS-FIVE

? Ask a question

Description

Flexible Manufacturing System (FMS) is a system in which Method of producing goods is readily adaptable to the changes in the product being manufactured. A flexible manufacturing system gives manufacturing firms an advantage in a quickly changing manufacturing environment.

Training kit Flexible manufacturing systems is a prototype of FMS which are currently being used in the industry. It consists of following equipment:

- CNC Lathe with Servo Motors;

- CNC Mill with Servo Motors;

- Gantry for Loading and Unloading from CNC Lathe Machine;

- Three Axes Robotic Arm for Loading and Unloading in CNC Mill Machine;

- Pallet Conveyor / Automated Guided Vehicle;

- Automatic Storage and Retrieval System.

Complete Flexible Manufacturing System is controlled through a Central Control Unit which is based on SCADA. Touchscreen is provided where user can decide the machining operation to be performed on respective machine along with a quantity. Alarms as well as safety features are also displayed on the screen to avoid any accidents.

CNC Lathe machine is a PLC Based machine with Servo Feed motors. It is equipped with slant bed and linear motion guideways. Hydraulic chuck is used for automatic clamping of workpiece.

Key features of CNC Lathe:

- Slant Bed with Linear Motion Guideways;

- Hydraulic Chuck with Hydraulic Powerpack;

- 8 Station automatic Turret;

- Servo Motors with Position Feedback for maximum accuracy.

Specifications of CNC Lathe:

- Centre Height: 150 mm minimum;

- Chuck Size: 150 mm;

- Chuck Type: Hydraulic with Hydraulic Powerpack;

- Swing Over Cross Slide: 80 mm;

- Distance Between Centre: 300 mm;

- Spindle Taper: MT3;

- Traverse X Axis: 80 mm;

- Traverse Z Axis: 270 mm;

- Tool Changer: automatic;

- No. of Tools: 8;

- Maximum Turning Diameter: 62 mm;

- Spindle Motor Power: 2,2 kW;

- Resolution: 0,001 mm;

- Rapid Traverse: 0,08 m/sec;

- Positioning: 10 micron;

- Repeatability: 20 micron;

- Lubrication system for Main Spindle, Guideways and other areas: Automatic Lubrication system to be operated through controller;

- Coolant: Flood coolant system of capacity of 40 liters;

- Mode of Operations: FMS, Individual;

- Communication with other machines and Central Control: Wireless Communication / Profinet Communication.

CNC Mill machine is a PLC Based machine with Servo Feed motors. It is equipped with Pneumatic Vice for automatic clamping and declamping of work pieces. 8 Station automatic tool changer is provided with pneumatic actuation.

Key features of CNC Mill:

- Linear Motion Guideways;

- Servo Motors with Position Feedback for maximum accuracy;

- 8 Station Automatic Tool Changer;

- Pneumatic Vice for auto clamp and declamp.

Specifications of CNC Mill:

- Travel X axis: 300 mm;

- Travel Y axis: 200 mm;

- Travel Z axis: 250 mm;

- Travel A Axis (4th Mill Axis): 360 Degrees;

- Table Size (L x W): 600 x 225 mm minimum;

- Axis Control: Simultaneous Three axis control;

- Job Load on Table: 60 kg min;

- Tool changer: Automatic Tool Changer through Software as per Industrial Controller;

- Tool Holder: As per ISO 30 standard;

- Spindle Motor Power: 2,2 kW with VFD;

- Spindle Motor Type: AC Motor;

- Spindle Speed Variation: Through Controller with Feedback;

- Spindle Speed Range: 300 RPM to 3000 RPM;

- Resolution X axis: 1 micron;

- Resolution Y axis: 1 micron;

- Resolution Z axis: 1 micron;

- X/Y/Z Cutting Feed Rate: 0,03 m/sec;

- X/Y/Z Rapid Feed Rate: 0,08 m/sec;

- Position Accuracy X/Y/Z: 10 micron maximum;

- Lubrication system for Main Spindle, Guideways and other areas: Automatic Lubrication operated through Software;

- Coolant: Flood coolant system of capacity of 40 liters;

- Mode of Operations: FMS, Individual;

- Communication with other machines and Central Control: Wireless Communication / Profinet Communication.

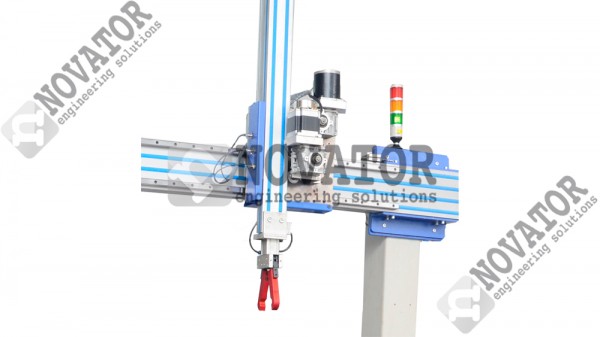

Gantry with Linear motion guideways is provided for loading and unloading from CNC Lathe Machine. It can pick up a round job from Pallet conveyor or AGC and load it into the CNC Lathe Machine. Pneumatic Gripper is provided which can be modified to pick up a job of up to 35 mm. Brake motor is provided for Z Axis.

Key features of Gantry:

- Brake motor for Z Axis;

- Linear Motion Guideways for horizontal as well as vertical axes;

- Pneumatic Gripper with a payload capacity of 2,5 kg;

- Position Accuracy of up to 0,02 mm.

Specifications of Gantry:

- Horizontal Travel: 3000 mm;

- Vertical Travel: 1200 mm;

- Gripper Actuation: Pneumatic;

- Programming: Standard G and M codes;

- Rapid Rate: 0,03 m/sec.

Robotic Arm is provided for loading and unloading from Mill machine. It is a Three/Four axes robotic arm with stepper motors used as feed motors. Linear motion guideways are provided on each linear axis.

Key features of Robotic Arm:

- Brake motor for Z Axis;

- Linear Motion Guideways for all linear axes;

- Pneumatic Gripper with a payload capacity of 2,5 kg;

- Position Accuracy of up to 0,02 mm;

- Can be operated individually without complete FMS operation.

Specifications of Robotic Arm:

- X Axis Travel: 1500 mm;

- Y Axis Travel: 1000 mm;

- Z Axis Travel: 1000 mm;

- C Axis (Optional): 270 Degree;

- Gripper Actuation: Pneumatic;

- Programming: Standard G and M Codes;

- Rapid Rate: 0,03 m/sec.

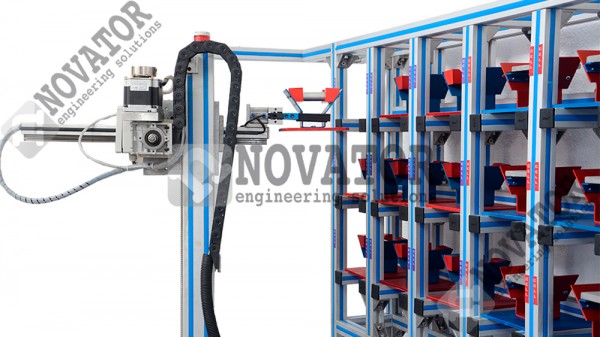

Automatic storage and Retrieval system is a storage unit with a robotic arm. It is actuated pneumatically. Workpiece along with a fixture is loaded on pallet conveyor which is then transported to individual machining centers with the help of either conveyor or an Automated Guided Vehicle.

Key features of Automatic storage and Retrieval system:

- Brake motor for Z Axis;

- Operation through standard G codes and M codes;

- Position accuracy of 0,02 mm;

- Three axes are provided with a feed rate of 0,03 m/sec;

- Homing facility is provide for all axes.

Specifications of Automatic storage and Retrieval system:

- X Axis Travel: 1500 mm;

- Y Axis Travel: 600 mm;

- Z Axis Travel: 1000 mm;

- Gripper Actuation: Pneumatic;

- Gripper Payload Capacity: 2,5 kg;

- Rapid Rate: 0,03 m/sec.

Conveyor is used to transport raw materials from ASRS to machining centers. Conveyor is constructed in a C shape with ASRS in the middle and Machining centers (CNC Lathe and CNC Mill) on either sides. User can manually control the speed of the conveyor either through Central controller or manually through VFD. Raw workpieces are transferred through a fixture which can hold a round bar of up to 35 mm diameter or a flat square plate of 130 mm.

Key features of Conveyor:

- Flex Belt with link mechanism which can take a turn in 180 degrees;

- Speed of the conveyor can be controlled through controller as well as through Variable Frequency Drive;

- Can be operated through standard G codes and M codes through central controller;

- Can be operated individually without complete FMS operation.

Specifications of Conveyor:

- Conveyor Travel: 5 m (C Shape);

- Motor Type: AC motor;

- Motor Capacity: 0,75 kW;

- Programming:Standard G and M codes;

- Payload Capacity: 20 kg.

Automated Guided Vehicle (AGV) which originally works on Program Guided principal but at the same time color guiding principal is used to maintain the accuracy below 10 mm. Step Servo Motors are used in Hytech AGV for each driving wheel. Feedback of these motors is taken to achieve highest position accuracy. AGV programming is done in the same way it is done for any two dimensional CNC machine. Coordinates of each point of the track can be easily found out with the help of autocad drawing. Red Colored strips are provided in track for each point. These color strips act as an additional measure to maintain position accuracy of AGV. Two photo sensors are provided for each wheel of AGV. These sensors are preprogrammed in such a way that they sense only red colored strips. Motion of each wheel will stop as soon as its corresponding color sensor is activated. That means AGV motion will stop completely as soon as both sensors sense red colored strips.

Key features of Automated Guided Vehicle:

- Path can be easily changed/modified;

- Various coordinates of the path can be easily generated from autocad drawing;

- Color sensors are provided on both wheels which will work as an additional measure to increase the accuracy and compensate for the missing pulses if there are any;

- Reference band is provided which will allow the user to reference the AGV in just two seconds;

- Can be moved in JOG;

- HMI display is provided to display actual coordinates;

- Encoder feedback is provided for each motor which increases the position accuracy;

- Number of stops/stations can be added without any extra expenditure.

Specifications of Automated Guided Vehicle:

- Operating Principal: programming of two driving wheels in simple coordinates;

- Battery: 75 A x 2;

- Data Entry: Through HMI (Touch Screen) or through Central Controller;

- Path Programming: Directly through HMI;

- Conveyor Length (Mounted on AGV Top): 400 mm;

- Maximum AGV Run: 60 m;

- Maximum Speed: 0,08 m/sec;

- Speed Variation: can be changeable directly through HMI;

- Mode of operations: FMS, Individual;

- Communication with other machines and Central Control: wireless.