Multi-Function Check Measurement kit

|

|

|

PLANB_FULLICONS-ONE

PLANB_FULLICONS-TWO

PLANB_FULLICONS-THREE

PLANB_FULLICONS-FOUR

PLANB_FULLICONS-FIVE

? Ask a question

Description

Product quality not only depends on the sophisticated machines & measuring instruments from a reputed brand but also depends upon their proper handling, storage, routine calibration and maintenance etc. Further we know measuring instruments are backbone of any manufacturing setup & as per inspection results people set their machine parameters and incorrect measurements results in improper machine setting, rework, rejection or unexpected quality issues. Furthermore any measuring instrument can do malfunctioning any time without warning apart from their routine wear and tear due to various reasons.

For this it is very essential to check every measuring instrument with less interval or prior to use but practically it's not so easy like in case of external calibration facility collect the instruments from shop floor, send them to appropriate calibration laboratory, issue alternative instruments, get back after calibration, compare old and new results, compensate those result values with instrument readings, communicate those changes to user etc. or alternatively maintain good inhouse calibration laboratory with so many calibration standards, controlled environment, skilled people etc. but up to some extent activities will be almost same as they were in case of external calibration facility.

If we analyze precisely both the above calibration facility involved physical movement of the instruments, paper work, communications & co-ordination of different people, inventory of instruments etc. but sometimes it causes inconvenience to user like late delivery of instruments, damages during transportation, human error in calibration, wrong interpretation & communication of calibration results etc. These circumstances may convert this important exercise into wastage of time, money and other resources. Besides doing all this work no calibration facility can give you the assurance of adequate working of your instruments till the next calibration will be performed.

Can we reduce:

- Physical movements of instruments, people and paper work

- Inspection failure, rework, rejection and unwanted scrap

- Dependency, delays and wrong interpretation of calibration results

- Calibration cost, instrument inventory cost and capital investments

- Measurement uncertainty, bias and linearity error

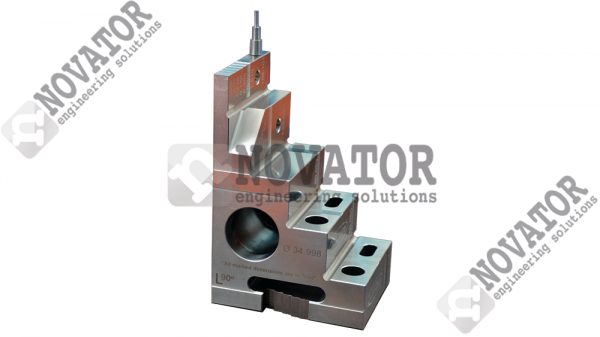

Quick Check works as a master gauge to calibrate or verify various measuring instruments daily or prior to use at workplace like Vernier Calipers, Micrometers, Depth Micrometers, Height Gauges, Depth Gauges, Bore Gauges, Internal Calipers, External Calipers, Micrometer Heads, Dial Gauges, Bevel Protractors, Try Square, V- Block, Electronic Probes and Combination Sets etc. Apart from that Quick check can verify instruments with different ranges, least counts, makes, models and types as available worldwide.

Salient features of the Quick Check are... Compact design, multi-function, multi-dimension, precise, all sides usable, simple, easy to use & no attachment or loosen accessories because it is very difficult to maintain master instruments with accessories at workplace area and sometimes improper selection & fitment of loosen parts incurred error in inspection process like slip gauges. Quick Check does not require special skills to handle any person with some basic knowledge of inspection & measurement can use it easily.

With respect to its construction & shape every contour, bore, slots, angle, pin, steps & relief have its own strong technical or functional reason and are arranged so beautifully to cater maximum instruments varieties. It covers parameters like length, dia, angle, depth, straightness, perpendicularity etc. Further related dimensions are laser marked at various places which makes Quick Check just plug and play device.

Due to its compactness & versatility it can be very useful for almost all type of manufacturing industries like Automobile, Aerospace, Railways, Shipping, Defence, Consumer Goods, Electrical, Electronics, Tool Rooms, Power Plants, Rubber, Plastic, Sheet Metal, Casting, Forging etc. In other way we can say Quick Check may be an integral part of any inspection process to improve overall accuracy, precision, stability, consistency and reliability of measurement system.