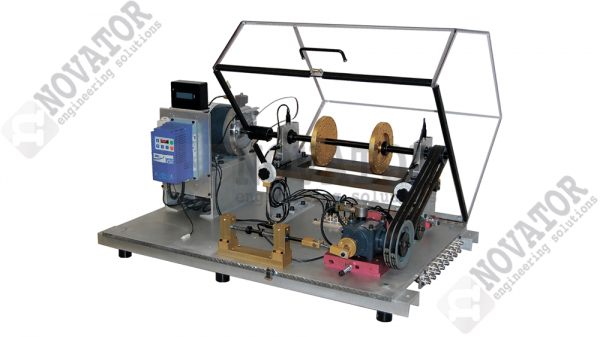

Machinery Fault Simulator (MFS)

|

|

|

PLANB_FULLICONS-ONE

PLANB_FULLICONS-TWO

PLANB_FULLICONS-THREE

PLANB_FULLICONS-FOUR

PLANB_FULLICONS-FIVE

? Ask a question

Description

The Best Tool Available for Learning Machinery Diagnosis

To gain an in-depth understanding of different vibration signatures, controlled experiments on a device that emulates real world machinery are needed. While analysis of a single machinery fault may be beneficial, there are many occasions when the analysis of the interaction between dynamic stiffness, resonance, and speed is essential in order to gain an understanding of real world vibration spectra. With the MFS, the expertise required to diagnose industrial machinery problems in well controlled experiments can be developed and enhanced. With a plant running at full production, it is virtually impractical to gain an understanding of the kinetics and dynamics of machinery without adversely affecting production and profits: The MFS enables offline training and experimentation which in turn will minimize production downtime.

Applications

- Balance training

- Shaft alignment training

- Alignment system assessment

- Coupling studies

- Bearing faults and load effects

- “Cocked” rotor

- Eccentric rotor

- Resonance studies

- Sleeve bearing studies

- Belt drive performance

- Mechanical rub

- Gearbox fault studies

- Reciprocating mechanism studies

- Foundation studies

- Signal processing techniques

- Variable speed/load effects

- Motor current analysis

- Rotor dynamics

- Operating deflection shape and modal analysis

- Optimize sensor mounting

- Sensor types (accelerometer, proximity probes, etc.)

- Vibration training

- Analyst certification

- Customized test bed for rotor dynamics studies and demonstrations